Precision Equipment Portfolio

TF-9DHD Infeed/Throughfeed Centerless Grinder

The TF-9DHD Infeed/Throughfeed Centerless Grinder uses computer controls to grind both hard and soft materials including catheters, medical guidewires, and spinal cord stimulators. Inside the compact footprint is a 15HP main spindle motor powering an 8.625” wide work wheel combining to remove more material faster, and with better surface finishes, than similar machines with narrower grinding wheels. The TF-9DHD is designed to enhance productivity through a simple control interface and automation integration.

CAM.2 Micro Grinder

The CAM.2 Micro Grinder can produce flats, radiuses, needle points, and non-linear shapes; the perfect machine to grind complex medical guidewires, dental parts, and small precision parts for various industries. Combining the latest in multi-axis servo motor control, submicron positioning, and an intuitive 15″ HMI, the CAM.2 offers unmatched performance. With the CAM.2’s full-fledged G-code underpinnings, direct integration with CAD/CAM packages is seamless. Previously unproduceable parts can be made easily, with minimal setup time, and with limited operator training.

GT-610 Centerless Grinders

The Glebar modular GT-610 Series of precision Infeed/Thru-feed Centerless Grinders remove more material faster, and with better surface finishes than competing machines. Applications for machines within this series include aerospace fasteners, automotive transmission components, engine parts, and valve stems, PCD drill bits, arthroscopic bone shavers, bone drill blanks, medical device components, and more.

Search By

Technologies

or Brand.

Applications | Technologies

Brands

Case Studies

P5K Gauging Machine

Revolutionize your metrology process with the Glebar P5K Gauging System – the fastest and most accurate solution for medical guidewire measurement. Scanning at a remarkable 160,000 diameter readings per second,

Thrufeed Centerless Grinder: GT-610 EZ

The Glebar GT-610 EZ is a lean version of the GT-610, bringing slide motion control to the operator at an affordable price point. Operating on a much smaller footprint than

P4K: Profile Metrology System

The Glebar P4K Gauging System is the world’s fastest and most accurate profile metrology system available for long parts or multiple short parts. It is the industry standard for measuring

Filler Spouts | GT-610

Challenge: A food equipment manufacturer approached Glebar to improve productivity and reduce costs for their food filler machines. The metal spout requires grinding for several reasons. They come in contact with

Increase Productivity by Cutting Zirconium Tubes with ECG | CS1-E

Current Process Zirconium tubes are cut one at a time using carbide tools on a lathe. A lathe cutoff leaves burrs requiring deburring to achieve a smooth surface finish. Carbide

Guidewires (Process Efficiency | CAM.2)

Challenge: To eliminate additional processes in the production of guidewires. The conventional process uses several machines to profile a shape in an interventional guidewire. Solution Glebar eliminated pre- and post- processes

Guidewires (Rapid Changeover | GT-9AC)

Challenge: A Medical device customer needed to rapidly changeover between a family of Nitinol guidewires having various lengths and geometries. Since the geometry of the components varied in length, the customer

Guidewires (Gauging | P4K)

Challenge: Lack of a clear, simple method to inspect the geometric profile of many components. Existing systems are slow, unreliable, and complex to operate. Solution Glebar’s P4K gauging system was designed

Robot Automated Catheter Tips & Holes

Thank you to all who stopped by to visit with us at MD&M West. Our engineers love discussing your projects and developing solutions. Guests viewed superior catheter tipping and hole

Catheter Tipping & Hole Forming Machines

In this challenging environment, we first want to say we hope all you – our valued partners and families – are healthy. Second, we want you to know that we

Catheter Tipping Characterization Process

We hope you and your families are holding up well at this time. CATHTIP continues to provide needed equipment and services to our valued customers. Some of you are turning

Catheter Cost Solutions

This month we’re serving up options. Options for how to keep YOUR projects moving forward in this atypical business climate. Because CATHTIP is fully-integrated we can offer you solutions to

NEW! Flex-Drill for Catheter Holes

We’ve been encouraged to see our customers thriving and busy with so many new developments – thank you for letting us be a part of your success. Speaking of new

CATHTIP Equipment Add-Ons

We love helping our customers! From flashless catheter tipping, to burr-free hole forming, our equipment produces the consistent, quality parts you need. Whether your project is manufactured in your cleanroom

RF Catheter Tipping

Your projects are in capable hands at CATHTIP. The teams creating your proof-of-concept catheter parts, prototypes and development processes are intimately acquainted with the best, most versatile, powerful machines on

Catheter Skiving Slotting Video

Let us introduce you to something new for your R&D or clean room repertoire: the CATHTIP Skive Capsule (patent pending). Slotting or skiving your catheter tubing just got easier.

Flex-Drill Power Feed

We are available to assist you with your projects from proof-of-concept to production. We continue to hear from you and innovation and acquisition are one result. We’d like to welcome

Endotracheal Tube Tipping

Does increased production sound interesting? In addition to flashless tipping, clean hole-drilling & higher yield of quality parts, we offer extensive customization of our tooling platform to meet your production

Elongated Shaft Hole-Drilling & Skiving

Unique applications may require unique solutions. Lean on our 25+ years of catheter manufacturing expertise to help engineer repeatable solutions and improve product quality, rate of production, & supplementary services.

Full Radius Tipping & Multi-Hole-Drilling

SPOTLIGHT ON: Integrated Tipping and Hole Drilling Solutions Power: CATHTIP RF tipping generators can generate enough heat to form the largest catheter tubes you need. Control: Experience the tightest resolution of heat

Radio Frequency Pigtail Curling

SPOTLIGHT ON: Pigtail Curling Process on RF Tipping Machines CATHTIP Radio Frequency tipping machines utilize precise closed-loop temperature control, allowing equal accuracy whether modifying delicate, thin-walled material or robust thick-walled

Closed Loop Control on your Magnum

SPOTLIGHT ON: Closed Loop Feedback & Control for Tube-Forming CATHTIP Magnum RF tipping machines can utilize any of the built-in closed loop control features for force, temperature, or current –

Tipping, Flaring, Bonding Categories

SPOTLIGHT ON: Tipping, Bonding, Flaring Our Magnum and Quantum RF tube-forming machines are designed to produce a variety of tube forming configurations, including tipping, bonding, flaring, with a simple tooling

Irregular Shapes – Bulb Tipping Process

SPOTLIGHT ON: IRREGULAR-SHAPED TIPPING You are NOT limited by simple tapers on our Magnum & Quantum tipping machines. Your irregular-shaped tips can be proven out, improved, & developed for production with

CATHTIP now a sister company to SYNEO Company

Happy Thanksgiving! We are thankful for you our loyal customers! This has been a unique year, to say the least, and we want to take a moment to express our

SPOTLIGHT ON: FLARING PROCESS

Technology is advancing at record-breaking speeds, and processes that worked in the past may not be the most effective today. That’s why at CATHTIP, we dedicate our efforts to providing

SPOTLIGHT ON: MD&M WEST 2022

We are excited to showcase our state-of-the-art catheter manufacturing technologies at MD&M West, April 12-14. Join us at booth #3101 where we will feature our Magnum Tube-Forming Machine, FLEX-Drill Hole-Forming

SPOTLIGHT ON: MICRO FLARING & SPECIALTY MANUFACTURING SERVICES

CATHTIP Your source for Specialty Manufacturing and leading edge drills with flow through technology. We understand that sourcing capital equipment may not be a viable option for proof of concept

SPOTLIGHT ON: EXPANDED OFFERINGS & HIGH DEMAND

The neurovascular and cardiovascular catheter markets have exploded, and with that we are seeing an increased need for our best-in-class catheter tipping and hole-forming solutions. At CATHTIP, we encourage our

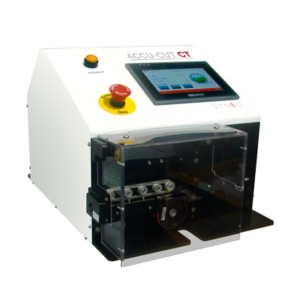

Automated Large Tube Cutting: Accu Cut CT & CTXL

The Accu-Cut CT Automated Large Tubing Cutter, based on the Accu-Cut 202L, is designed for applications that demand high traction and high power indexing. Ideal for materials up to ½”

Tooling: Medical Extrusion Tools

R&D Engineering extrusion tools are machined with high-quality materials and are extremely accurate and durable machines. We offer a large catalog of tool designs from a wide range of sizes,

Printing System: Accu Print

SYNEO Accu-Print Catheter Printing Systems combine SYNEO’s best-in-class tubing materials handling and inspection techniques with pad and inkjet printing functions to meet precision printing specifications for unique medical devices. Accu-Print

Infeed/Thrufeed Centerless Grinder: GT-610

The Glebar GT-610 Infeed/Throughfeed Precision Centerless Grinder features a compact design that provides high horsepower, high rigidity, and superior slide positioning. Customizable controls are designed to integrate full turnkey automation

Catheter Drilling and Cutting System

SYNEO’s Automated Catheter Drill and Cut systems allow engineers to produce finished, drilled and precision cut-to-length catheter components in a continuous and fully automated manufacturing process. Raw materials can be presented

Catheter Laminating: Reflow Clam Shell

The CT Reflow Clam machine differs from the CT Reflow Chamber machine because of its ability to be programmed to skip over various parts of a catheter assembly, therefore removing

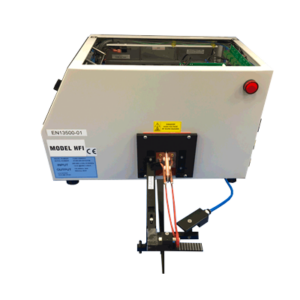

Catheter Tipping: R&D Radio Frequency

Our Radio Frequency Tipping Machine uses RF energy which improves application processing speed as it automatically starts at the desired temperature. Additionally, it provides more flexibility to the dies when

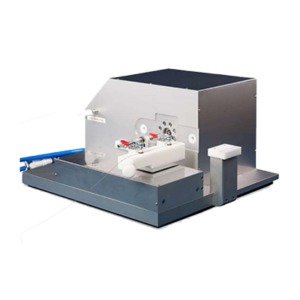

Pleating & Folding: PTF 120

The PTF-120 is a fully automated machine and can pleat and fold balloons with a length of approx. 100 mm. The balloon products are clamped on a stable product table

Stick Tube and Wire Feeder

Highly regarded among medical device manufacturers for its precision, speed, and adaptability, the Accu-Cut 202L Automated Tube Cutter is known for its clean, square corners and precise lengths with convenient

Laser Measurement System (LMS)

Interface Catheter System Model LMS-100 is a bench-top measurement system designed specifically for catheter balloons. The system offers a non-contact solution to the typical problems encountered in the dimensional measurement

CR-60-HC

The Interface CR-60-HC Stent Crimping Machine is developed for the crimping of balloon expandable bio absorbable stents. Key Features Stent and balloon positioning outside of crimper head. Crimp head can

Laser Marking: Accu Lase v200

The UV Laser Workstations enable greater process capability in precision marking, tube cutting and complex hole making. SYNEO’s Accu-Lase products target a wide range of materials, including polyimide and Pebax

Coil Winder: 503 Single Filar

EBD Coil winding technology is developed specifically to wind micro coils for minimally invasive medical devices. Our coil winders can wind coils down to .001″ diameter wire on a .010″

Flexible Stent Crimping: CR-240 FSCP

The CR-240-FSCP Flexible Stent Crimping Platform is developed for the crimping and transfer on or into the delivery system. Both balloon expandable and self- expandable stents up to 220 mm

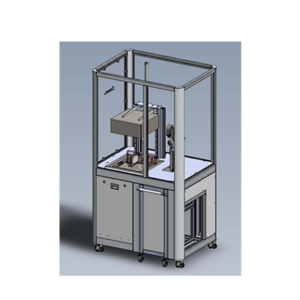

Automation Process

At MMT Automation, we follow a defined process flow for Equipment Development & Design; from Planning through Specification, Design, Construction, Testing & Installation. This process supports a typical Gamp5 Validation V-Model.

Extrusion Die Stretch 3×68

The Extrusion Die Stretching Machine (figure 1) performs hot die draw-down of plastic tubing used in catheter production. The process enhances material strength and improves O.D. tolerances. The machine can

Dual Feeding: Accu Feed DFS

The Dual-Feed system consists of two feeding processes mounted onto a high-quality, aluminum extruded, anodized rotary stand. This catheter manufacturing tube feeding machine provides precise alignment for variable cutting production.

CNC Wheel Dressing Machine: DM-9CNC

The Glebar DM-9CNC is a standalone dressing machine designed to dress 9″ (229mm) diameter by up to 10-1/8″ (257mm) wide wheels used on the PG-9BHD and PG-9DHD Plunge Grinders. It

Wheel Dressing Machine: DM-9B

The Glebar DM-9B is a standalone manual dressing machine designed to dress 9″ (229mm) diameter by up to 10-1 /8″ (257mm) wide wheels used on the PG-9BHD and PG-9DHD Plunge