At MMT, we are proud to offer top-notch services and support for catheter and guidewire manufacturing. Our services cater to a diverse range of OEMs and contract manufacturers. Whether you are in the research and development phase or require high-volume manufacturing, we have the capabilities to support your needs.

Our manufacturing services can be customized to your requirements, offering flexibility in choosing specific services for your project. Whether you need cut-to-length, hole forming, tipping, flaring or bonding, or component assembly services, you can be assured of a seamless and efficient manufacturing process.

Partner with us to experience the highest standard of catheter and/guidewire manufacturing services tailored to meet your unique needs.

Cut-to-Length Service

Square and burr-free cut ends and precision lengths are critical for minimizing tolerance stack-ups or reducing the risk of butt weld failure. For medical device manufacturers, our customizable equipment line is designed to create a competitive advantage for our catheter manufacturing customers.

At MMT, we maintain a multi-machine cell of SYNEO Accu-Cut machines to handle a wide range of tubing and catheter shaft applications. Accu-Cut 202L, 700L, CTXL tube cutting machines, and quick-turn tooling resources are available to cut a wide range of braided and non-braided shafts and materials.

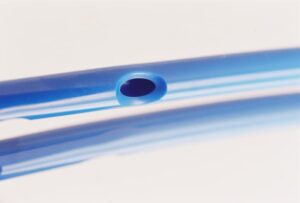

Hole Punching, Drilling and Cutting Services

Precise, burr free holes in catheter bodies are critical to catheter device performance and patient well-being. Manual and automated SYNEO Accu-Drill and CATHTIP 400 Series hole-forming machines are available to process various catheter hole drilling and punching applications.

Our team of dedicated applications experts, coupled with our robust line of precision equipment and tooling offerings, provide solutions for round, oval, odd-form, and off-center skive hole punching applications.

Our hole drilling applications experience and cutting tools featuring Hollow Core Sharpening Technology, single or multi-lumen catheter shafts with complex hole configurations or design patterns are achievable, featuring hole sizes as small as .005″.

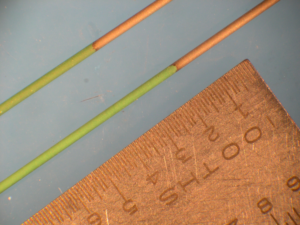

Guidewire and Mandrel Tip Grinding and Tip Forming Services

Manual wire deburring and tip grinding is an inconsistent, time-consuming, and costly process. At MMT, we maintain a SYNEO Accu-Tip Automated Tip Grinder (ATG) to serve our customers’ R&D and low-volume tipping needs. Small diameter, nitinol or stainless steel guidewires, stylets, or mandrels with radiused or chamfered ends are examples of the tipped component services we provide.

Catheter Tip Forming & Bonding Services

The ability to manufacture flashless and burr-free catheter tips is essential to essential to ensuring patient well-being through atraumatic device introduction and delivery.

Our manufacturing services facilities maintain SYNEO Accu-Tip and CATHTIP Magnum and Quantum radio-frequency tipping machines and plastics engineering resources to serve the catheter tip forming needs of our customers.

Our robust line of tip-forming, flaring, and bonding equipment can quickly and repeatably provide smooth, accurate transitions for all your catheter devices.

We offer precision tipping and bonding of polyurethanes, nylons, and other thermoplastic materials required to fabricate catheters and other minimally invasive medical devices. Our quick-turn, in-house machine shops can provide virtually any tip-forming tooling necessary for any specialty tip shape needed.

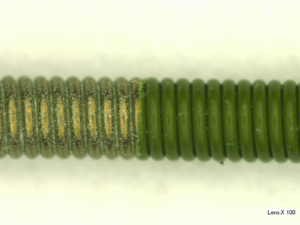

Identification & Surface Attribute Services

Surface modification through laser marking or sandblasting can be an excellent alternative to traditional depth mark printing on catheters or guidewires. These same surface modification processes can also be leveraged for increased adhesion with glued or insert molded components.

Together with out partners, we offer laser marking (laser etching) services, printing services and micro-blasting services for surface removal, serialization, and marker band applications.

Need tubing selection or extrusion support?

Through our robust brand portfolio, MMT maintains partnerships with extrusion houses specializing in medical-grade extrusions, including silicone, PTFE, and Pebax®. Let us connect you with our go-to extrusion partners to get you on the path to success!